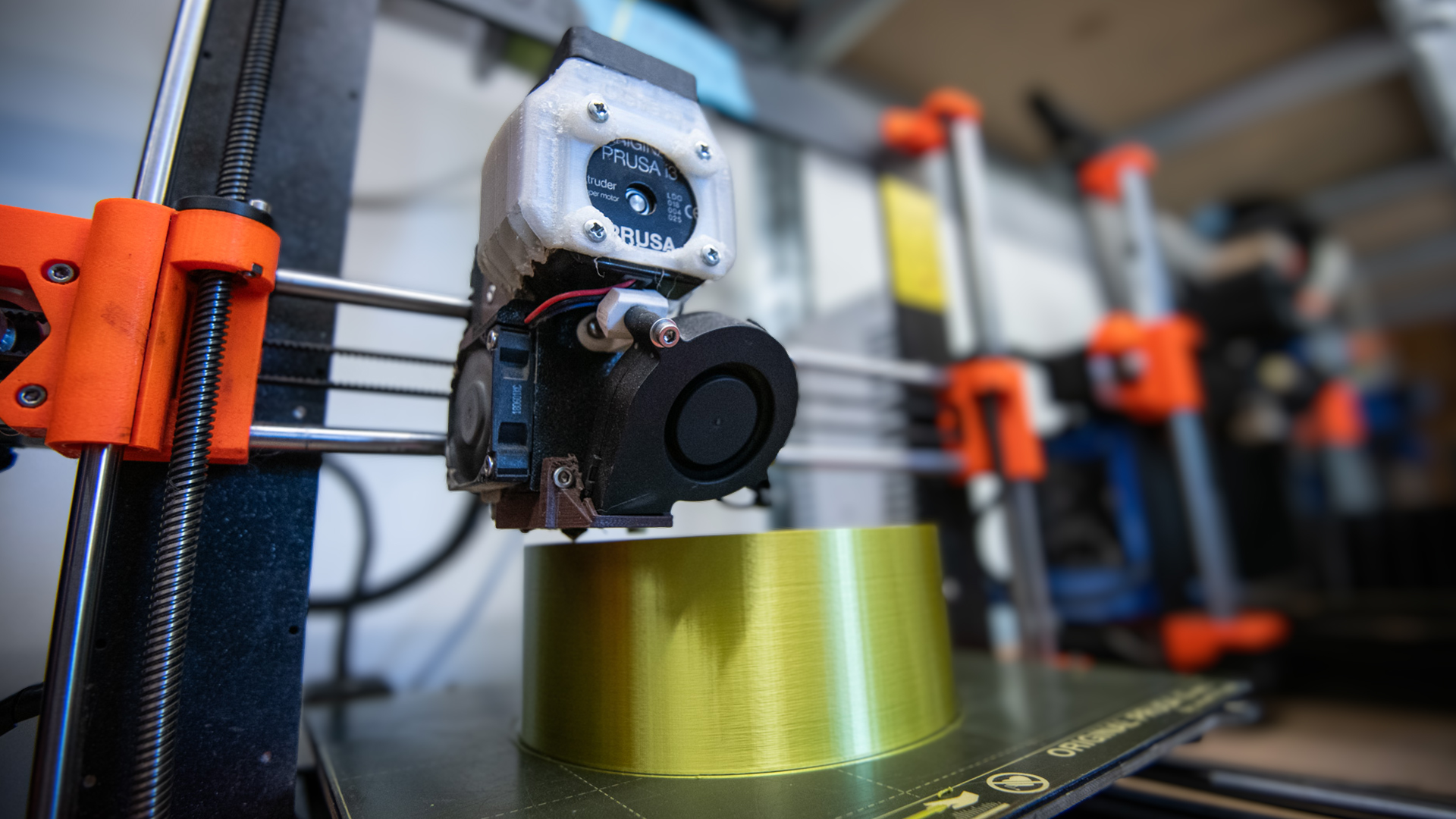

How to 3D Print in Summer: Mastering the Process with Tips from Vojta!

During the summer, higher temperatures can pose challenges for 3D printing with materials such as PLA and PLA+. In this article, Vojta shares valuable insights on how to avoid extruder jams and print without complications. Additionally, we recommend some temperature-resistant materials that handle the heat more effectively.

As the summer months are here, we want you to enjoy stress-free 3D printing with a smile. We understand that higher outdoor temperatures can present some minor hurdles for 3D printing, but fear not—we have several useful tips to help you easily manage your prints even on hot summer days.

Ventilation Works Wonders

When printing with materials like PLA or PLA+, it's important to be aware that the extruder may occasionally jam or clog, especially when the ambient temperature is 25°C or higher. This issue is particularly relevant for printers equipped with all-metal extruders.

So, how can you prevent it? If you have an enclosed printer, open the printer's enclosure or direct a standing fan towards the extruder. For the fortunate ones who have access to an air-conditioned room, this is a definite advantage, particularly for larger-scale printing setups.

Furthermore, remember to regularly clean the extruder's cooler from dust and debris to significantly improve its cooling efficiency.

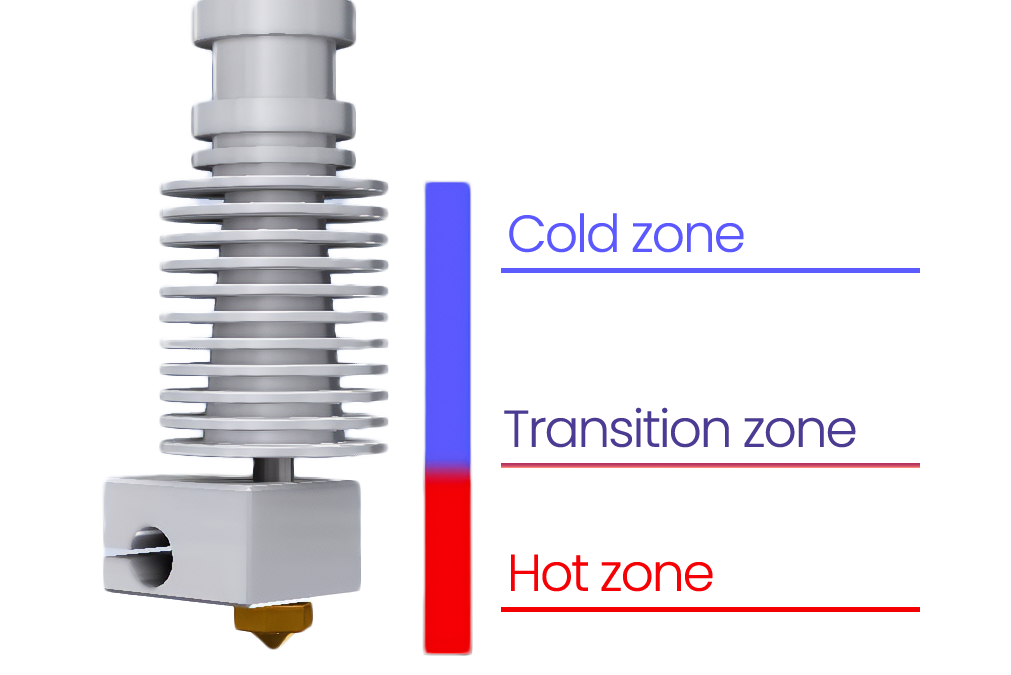

The Importance of Melting Temperature

The melting point is a critical factor affecting 3D printing on hot days. PLA and PLA+ have a melting temperature of around 55°C, which means that the material in the extruder can start softening and increasing friction during extrusion in high outdoor temperatures. In extreme cases, this can lead to a complete extruder jam.

How can you tell if cooling is an issue?

The initial stages of the print may proceed smoothly, and the first layers look perfect. However, once the extruder heats up, it might start skipping, clicking, or even stop extruding altogether (typically occurring within 30 minutes of starting the print). Caution! In some printers, prolonged insufficient cooling can cause wear and deformation of the PTFE (Teflon) tube, which will then require replacement.

Opting for Temperature-Resistant Materials

To avoid stress from high temperatures and the worry of whether your extruder is still functioning, we recommend considering temperature-resistant materials such as PETG, ABS, PC-ABS, or ASA.

These materials have higher melting points, making them much more resilient to elevated environmental temperatures. Printing with them during the summer goes smoothly, allowing you to enjoy your print with a drink in hand.

Melting Points of Materials:

ABS - 94°C

ASA - 96°C

PCABS - 115°C

PETG - 85°C

Enjoy the summer, and may your 3D printing experience be comfortable regardless of the weather.

We're glad you're printing with PM!